| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Xrido

Model Number : Customizable

Certification : CE ISO TUV

MOQ : 1 set

Delivery Time : 5-30 word days

place of origin : Henan, China

video outgoing-inspection : Provided

machinery test report : Provided

core components : Bearing, Gearbox, motor, Pressure vessel, Gear

model number : Y81F-400A

warranty : 1 Year

material / metal processed : Brass / Copper, Alloy, Carbon Steel, Stainless Steel

key selling points : Long Service Life

Product name : Metal Scrap Iron Aluminum Baler

Baler Density : >=2000 kg/m 3

Single Circling time : 120minute

Baler Size : 600*600 mm

Packaging Material : Paper, Plastic, PET bottle

Type : Hydraulic Metal Baler

Overall size : steelmaking plant. recycling processing and metal smelting industry.

Compression Chamber Size : 20500*2000*1200 mm

Bale discharging mode : Turn over/Side push

Condition : New

Marketing Type : Hot Product 2019

Warranty of core components : 1 Year

Applicable Industries : Garment Shops, Building Material Shops, Machinery Repair Shops, Restaurant, Food Shop, Construction works

Showroom Location : None

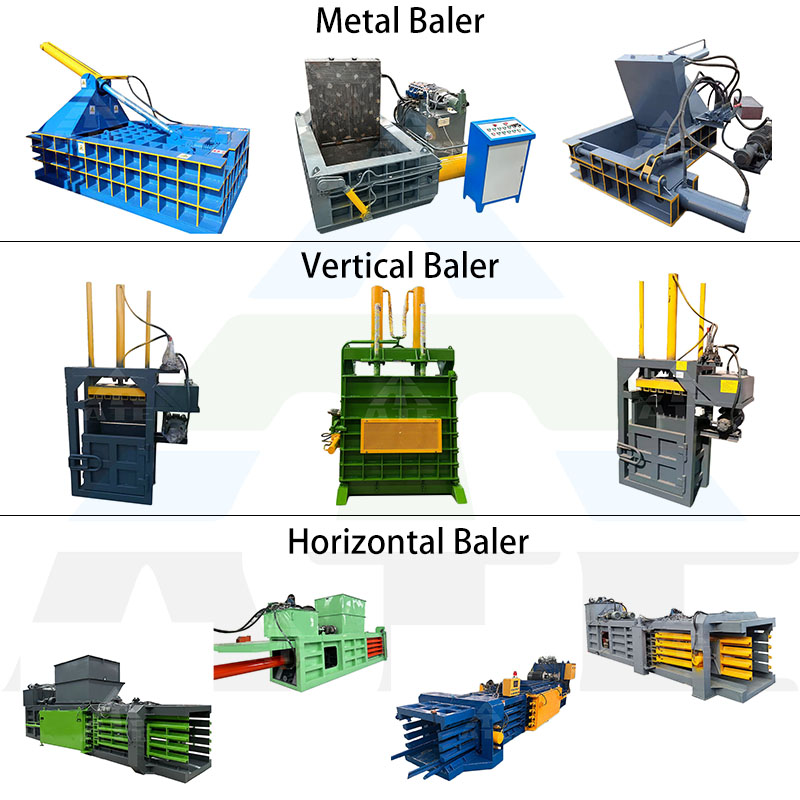

Metal briquetting baler, an industrial equipment that combines modern mechanical technology and environmental protection concepts, is reshaping the new form of metal with a huge force of 10,000 tons. In the broad arena of metal recycling and reuse, it plays an important role, not only greatly improving the utilization efficiency of metal resources, but also promoting the vigorous development of the circular economy. This article will explore in depth how this equipment can inject new vitality into the metal industry in its unique way from multiple dimensions such as the working principle, type, application field, market status and future development trend of the metal briquetting baler.

| Model | Nominal force(KN) | Chamber size(mm) | Baler size(mm) | Capacity(KG/H) | Single cycle time(s) | Motor power(KW) |

| XRD-125A | 1250 | 1200x700x600 | 300x300 | 1200-1800 | <=100 | 15 |

| XRD-135A | 1350 | 1400x900x700 | 350x350 | 1800-2200 | <=110 | 22 |

| XRD-160 | 1600 | 1400x900x800 | 350x350 | 2000-2800 | <=120 | 22 |

| XRD-160A | 1600 | 1600x1000x800 | 400x400 | 2000-3500 | <=120 | 22 |

| XRD-160B | 1600 | 1600x1200x800 | 400x400 | 2200-4000 | <=130 | 30 |

| XRD-200A | 2000 | 1600x1200x800 | 450x450 | 2500-4500 | <=130 | 30,37 |

| XRD-250A | 2500 | 1800x1200x900 | 500x500 | 4000-6000 | <=140 | 44,60 |

| XRD-250B | 2500 | 2000x1400x900 | 500x500 | 5000-6300 | <=150 | 44,60 |

| XRD-315A | 3150 | 2000x1400x1200 | 500x500 | 5000-6500 | <=150 | 60,74 |

| XRD-315B | 3150 | 2000x1750x1200 | 600x600 | 5000-7000 | <=160 | 60,74 |

| XRD-315C | 3150 | 2400x2000x1200 | 600x600 | 6000-7500 | <=160 | 74 |

| XRD-400B | 4000 | 2400x2000x1200 | 600x600 | 7500-9000 | <=160 | 90 |

Working principle of metal briquetting baler

As the name suggests, the metal briquetting baler is a device that can compress and pack scattered metal waste (such as scrap steel, scrap aluminum, scrap copper, etc.) into regular shapes (such as rectangular blocks). Its working principle is mainly based on the hydraulic transmission system, and the hydraulic oil is transported to each actuator (such as the main pressure cylinder, door cover cylinder, door opening cylinder, etc.) through the hydraulic pump, thereby driving each part of the equipment to complete a series of actions such as pre-pressing, closing, compression, pressure maintenance, and pressure relief.

Final Products

|

|

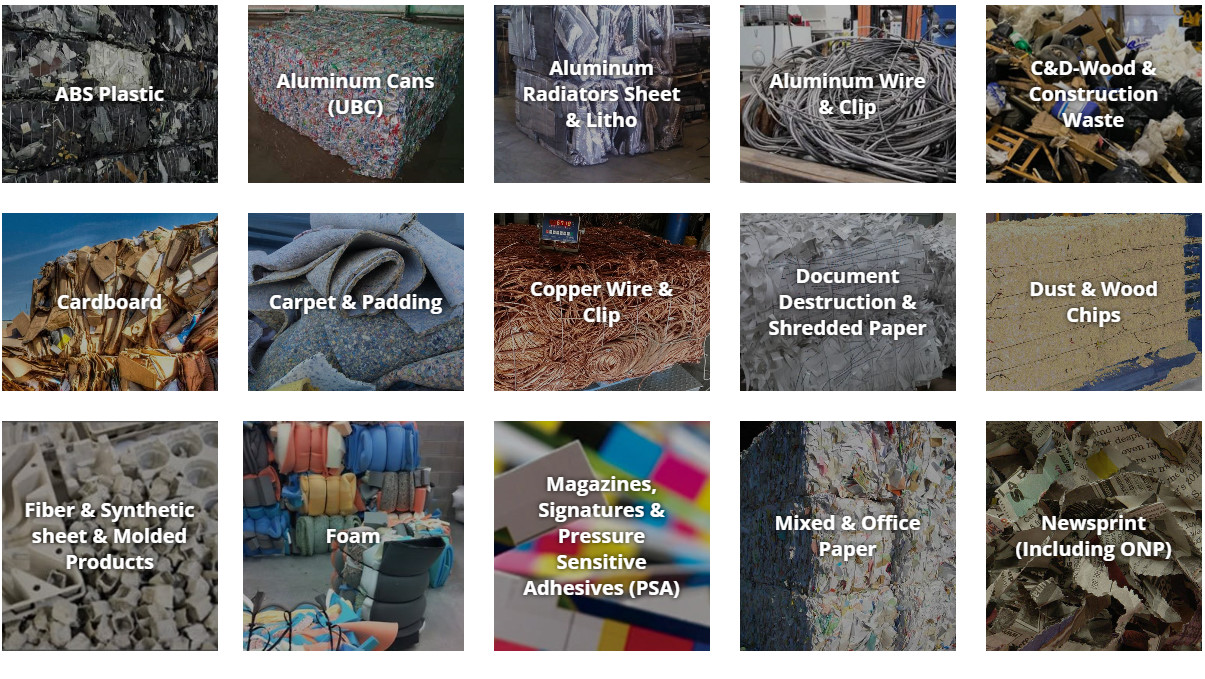

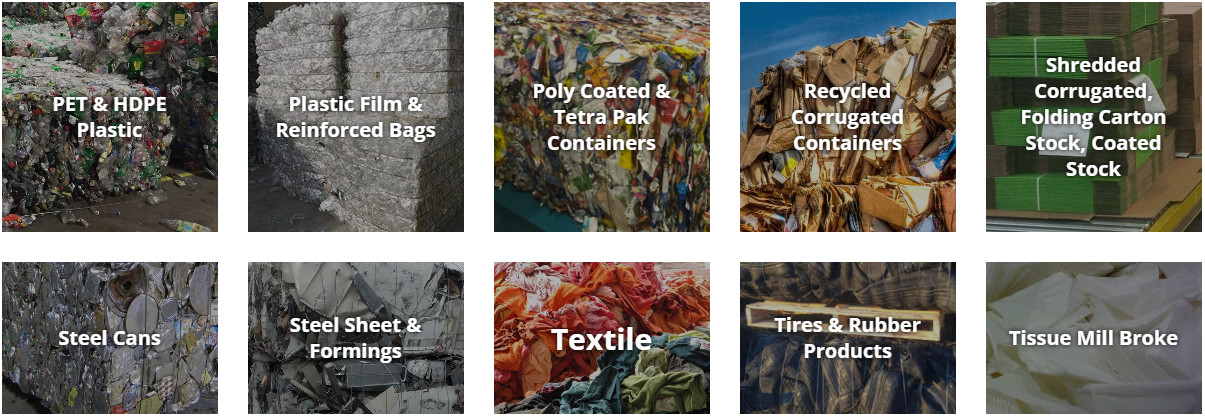

Waste Aluminum Scrap Metal Recycling Baler Aluminum Radiators Sheet Litho Recycling Balers Images |